Manufacturing and Materials Technology (FWT)

The development of new products is a central engineering task that can only be mastered on an interdisciplinary basis, i.e. in cooperation between product development, production and materials engineering. This is due to the fact that the component properties required in development are significantly influenced by the individual process steps from raw material or semi-finished product to the finished component. In view of the high level of development of available processes, the associated issues are considered a priority topic for research work in manufacturing technology. The primary objective of the Manufacturing and Materials Engineering research area is process (chain) optimization and control to improve component quality and resource efficiency in additive and machining processes using software-based methods. The research area is divided into the two groups Cutting (Prof. Schulze) and Additive Manufacturing (Prof. Zanger). The common strategic topics are surface engineering, sustainability and digitalization.

Contact:

Prof. Dr.-Ing. habil. Volker Schulze

Topics

Precision Machining |

Gear Engineering |

Additive Manufacturing |

|

|

|

| Contact: | Contact: M.Sc. Andreas Hilligardt | Contact: |

|

CZS Center KRAFt CZS Center for Circular Economy and Resource Efficiency via Additive Manufacturing Technologies |

Simon Linnemann, M.Sc. Marvin Rothmeier, M.Sc. Marvin Dornick, Dipl.-Ing. Prof. Dr.-Ing. Frederick Zanger |

01.04.2025 - 31.03.2031 |

|

AddInf Production of metal-metal interpenetrating materials by shaping in a partially liquid state |

Nico Ulff, M.Sc. |

01.01.2025 - 30.06.2027 |

|

AddDEM Characterization of technical powders for multiscale modeling of particle processes using the example of metallic additive manufacturing |

Kai Drechsel, M.Sc. |

01.05.2023 - 31.10.2024 |

|

AddBroach Sustainable production of near-net-shape semi-finished products by means of binder jetting using the example of broaching tools |

Daniel Mayer, M.Sc. Johannes Schubert, M.Sc. |

01.05.2023 - 31.10.2024 |

|

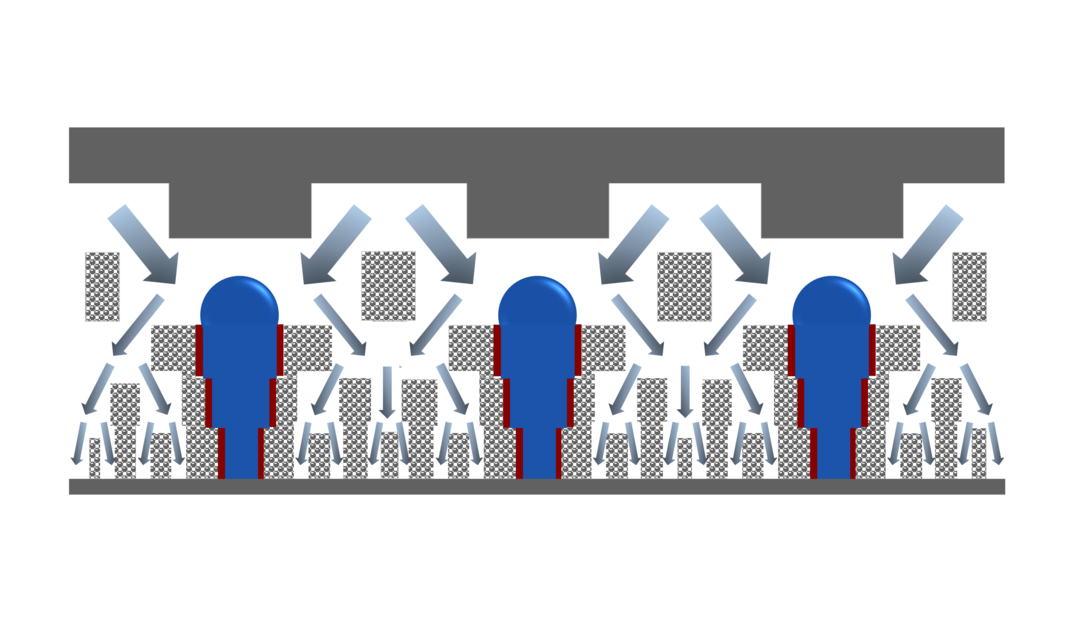

MultiPower Spatially optimised manufacture of a power module using stereolithographic multi-material fabrication of ceramic 3D substrates with embedded conductive structures |

Chantal-Liv Lehmann, M.Sc. Prof. Dr.-Ing. Frederik Zanger |

01.04.2023 - 31.07.2025 |

|

AddXChange Holistic qualification of copper for the binder jetting process with targeted porosity adjustment on the basis of heat exchangers for electromobility |

Daniel Mayer, M.Sc. Johannes Schubert, M.Sc. |

01.01.2023 - 31.12.2024 |

|

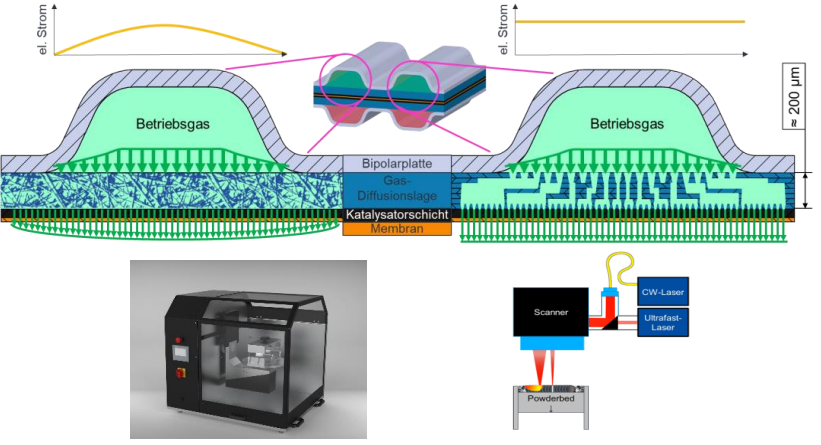

AddFlow Flow-adapted components for fuel cells through additive-subtractive manufacturing with adjustable surface function (hydrophobic, hydrophilic) |

Maximilian Frey, M.Sc. |

01.01.2023 - 31.12.2024 |

|

AddBite Development of patient-specific additively manufactured mandibular implants with biotechnology-inspired functional lattice structures |

Nico Ulff, M.Sc. Prof. Dr.-Ing. Frederik Zanger |

15.08.2022 - 31.07.2025 |

|

AddAlB4C Aluminum-B4C composites for powder bed-based selective laser melting. |

Victor Lubkowitz, M.Sc. |

01.07.2022 - 30.06.2024 |

|

KADDISH Cooling channels in the additively manufactured grooving tool |

Patrick Fischmann, M.Sc. |

01.02.2022 - 31.07.2023 |

|

AddPEM - Additive manufacturing of graded flow structures for po Additive manufacturing of graded flow structures for polymer electrolyte membrane (PEM) fuel cells. |

Victor Lubkowitz, M.Eng. Maximilian Frey, M.Sc. |

01.01.2022 - 31.12.2023 |

|

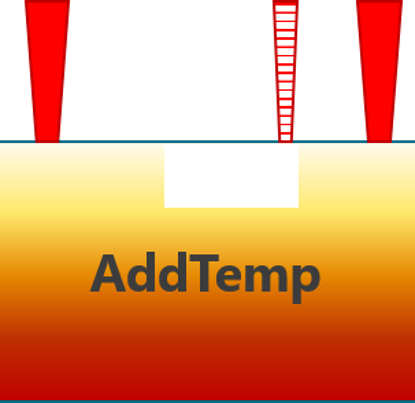

AddTemp Additive manufacturing of specific microstructures through local and global temperature control |

Kai Drechsel, M.Sc. |

01.01.2021 - 31.12.2024 |

|

ICM Junior Research Group Advanced Manufacturing A versatile and universally applicable manufacturing technology for the development of mobility solutions for tomorrow and for production technology itself. |

Steffen Kramer, M.Sc. Prof. Dr.-Ing. Frederik Zanger |

01.10.2020 - 30.09.2025 |

|

DFG GRK 2078: International Research Training Group CoDiCoFRP Integrierte Entwicklung kontinuierlich-diskontinuierlich langfaserverstärkter Polymerstrukturen |

Jannis Langer, M. Sc. |

01.04.2015 - 31.03.2024 |